Simulation of additive manufacturing processes for the production of metal components

May 11, 2021 2021-05-20 22:38Simulation of additive manufacturing processes for the production of metal components

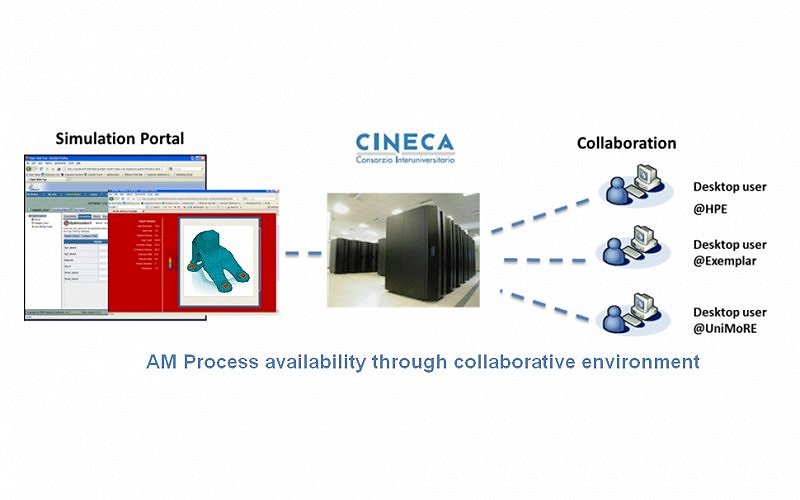

Additive Manufacturing is creating huge interest across all industrial sectors, due to its advantages over more traditional manufacturing processes. These advantages include not only the possibility to generate any shape, but also to reduce the number of parts required to obtain that shape. In addition, there is very little waste of material since only what is actually needed is used. This technology is relevant in the manufacture of turbine blades for energy and aero applications. However, components having complex shapes with internal cooling channels that are very challenging from the manufacturing point of view. Additive Manufacturing processes have been proven to ensure lower cost, use a wider range of alloys and result in higher mechanical strength. HPE, an Italian SME, is a flexible, agile and innovative provider of engineering solutions and technology to the world’s automotive, motorsport, automation solution and defence sectors. This experiment will demonstrate the use of Cloud-based HPC simulations in Additive Manufacturing. It will result in widely available services for the simulation of Additive Manufacturing easily accessible by SMEs. EXEMPLAR is a company founded by the Politecnico di Torino University, which provides services for Computer Aided Engineering projects. Its focus is on the world of virtual prototyping and covers Engineering Services, Methodology development, Process Automation and Software Development. EXEMPLAR provides application expertise in this experiment. The HPC expertise and resources were provided by the Italian HPC centre CINECA.

Fortissimo_SuccessStory_804_HPE_0.pdf

The Challenge

Additive Manufacturing (AM, also called 3D printing) technologies are generating huge interest in all industry sectors, as they enable the rapid design and manufacture of prototypes and products. However, there are challenges associated with using these technologies, such as component failure due to issues with layer deposition. There are multiple points during the fabrication process when the component being manufactured may fail due to this. Post-production failures of apparently complete parts can also occur.

The Solution

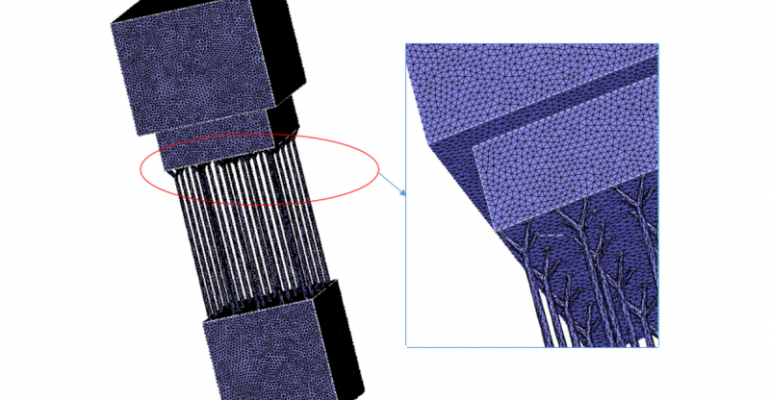

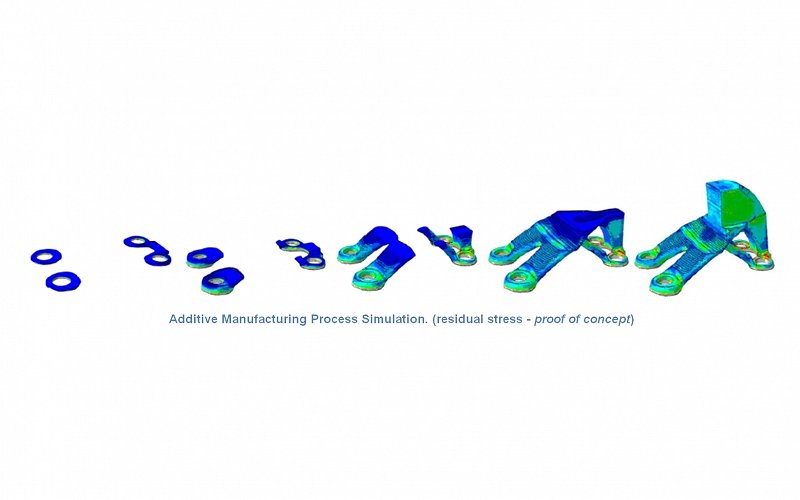

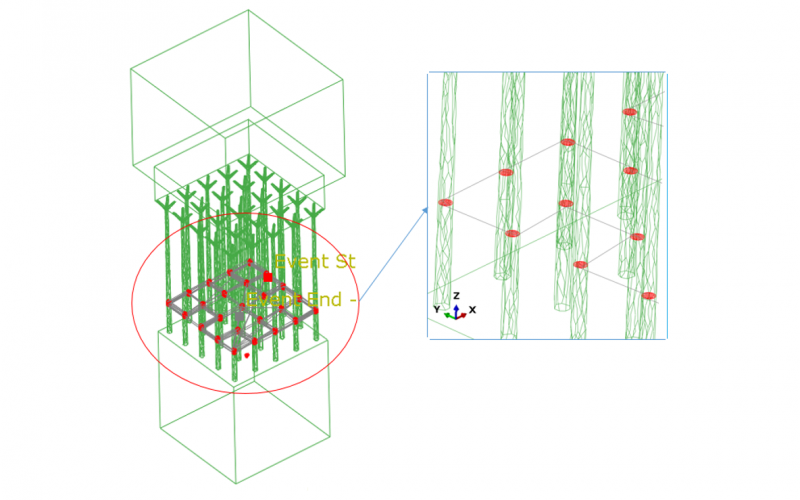

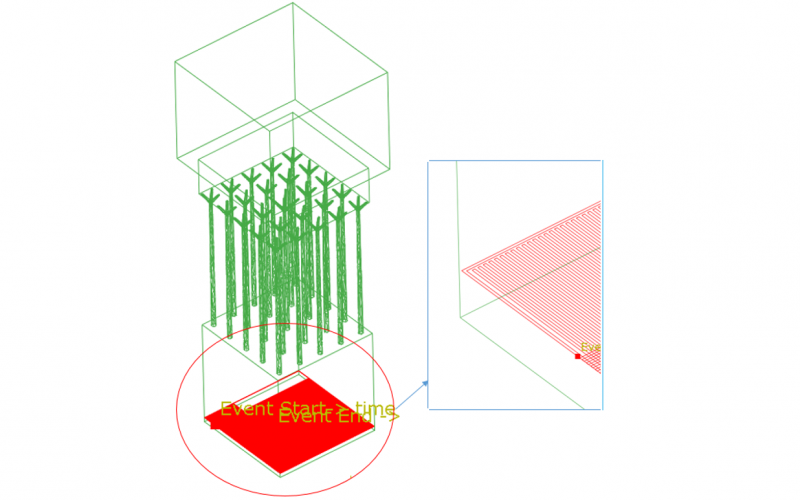

This experiment provided a numerical analysis environment which enables users to forecast the results of the AM process using cloud-based HPC simulation.

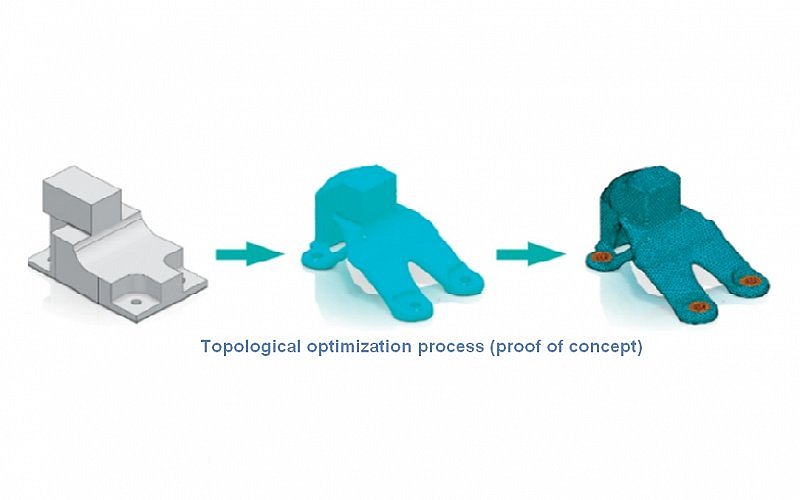

The forecasting tool is able to predict the stress state of the final component, as well as how the product deforms due to differential cooling during the manufacturing process. The multi-scale and multi-physics nature of the problem has been captured in the tool, allowing engineers to better understand this complex manufacturing process. This approach has created a robust solution by identifying which parameters most impact the quality of the final result before production begins, and which, therefore, need to be tightly controlled.

Business Impact

The impact this experiment for HPE has been to increase the effectiveness of its optimized AM solutions. The major benefits are a reduced time-to-market and a reduced number of defective parts, thanks to a closer match between the initial design and the manufactured part. This has consequently lowered costs.

As regards the reduction in time required for tuning the AM process, there were two main outcomes. Thanks to this experiment, build failures and multiple design loops can now be avoided. The same benefits for HPE could be applied to any SME that purchases the service via the Fortissimo Marketplace. The results of the experiment are expected to increase HPE’s market share by 50% and reduce costs (thanks to the lower levels of material wastage) by €90,000 per year.

EXEMPLAR is able to offer the technology developed here as a commercial service under an SaaS model, with a potential annual turnover of €125,000.

Benefits

- HPE can reduce time-to-market of their products

- The number of defective parts can be reduced

- Consequent reduction in costs of up to €90,000 per year

- EXEMPLAR expects an annual turnover of €125,000 from SaaS offer

Organizations Involved

End User: HPE (High Performance Engineering)

Application Expert: EXEMPLAR srl & University of Modena and Reggio Emilia (UNIMORE)

HPC Expert & Centre: CINECA

Recent Comments